We love it when our clients are as committed (or more!) to the design as we are.

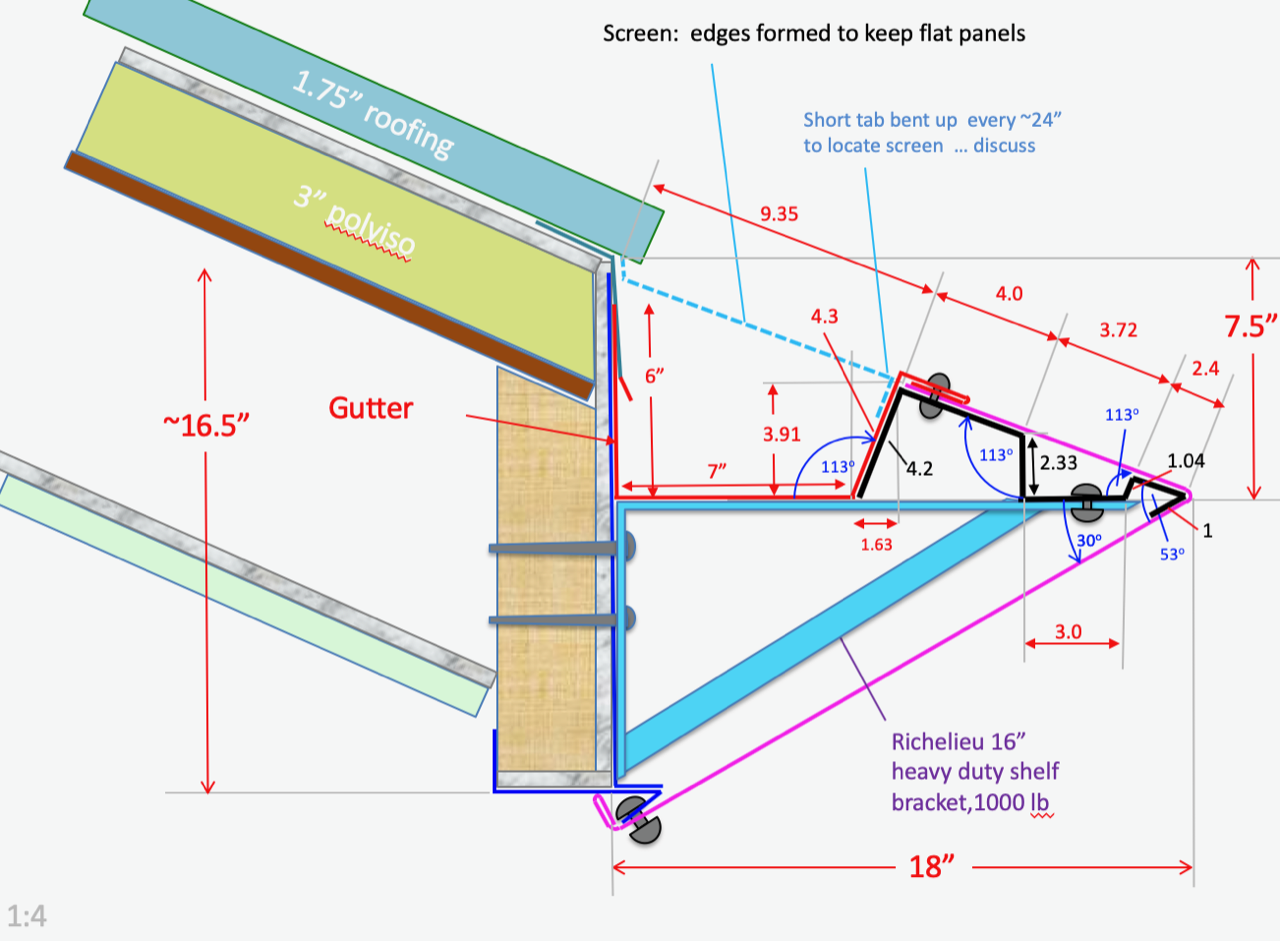

One of these amazing clients, Roger, is utilizing his engineering knowledge (normally applied to his work in the aerospace industry) to act as General Contractor for the remodel of his residence in La Canada. Frustrated by the inability of the roofing/sheet metal contractors to realize the vision for the tapered metal fascias on the undulating gable roof, Roger started drafting details himself to explain the work, and didn’t stop until he identified a company willing to take on the challenge. They are, reportedly, not cheap, but Roger says the relief of getting the fascias done right (and strong enough to stand on!), is worth it. And we love the results…

Check out more from the LCF Residence here.

Fortunately we had some heavy rain after erecting the first sections of eave, testing two different conditions: 1) hidden gutter; 2) flat panel where shedding of pine needles is imperative. The original eaves extended so low that they blocked the view for tall folks like me. The taper was conceived as and attractive way to increase the overhang without blocking the view. The test sections produce the desired extra shade (of curse) but were a disaster in terms of shedding water. Instead of launching off the edge, the water stuck to the underside and by the time it broke free it was traveling towards windows/doors. In heavy rain most of it struck the glass and door sills. The contractors, Eddy and Art Burnell (Burnell Sheet metal, 818-381-2625) mocked up a variation which extends the top plane about 5/8″ beyond the underside to create a slight overhang at the outer edge. The water now drips off the edge so the undersaide remains dry and free of water marks. At higher flow rates water launches further away from the building as if the overhang was even larger. The change in appearance is negligible. I’ll post more photos once we have the whole east side is done including both eave ….and gables which use 20 gauge metal deck to support the 22″ wide extra overhang. For the gable it is the slanted underside which extends about 1″ past the flat upper face to divert water that would have trickled down the underside.